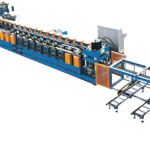

The Characteristics of Cold-formed Steel in Cold Roll Forming Machine

Ⅰ. About cold-formed steel processed by cold roll forming machine

The steel production method is roughly divided into two categories: hot working and cold working. Cold-formed steel is produced by cold working. Cold working includes stamping and drawing.

The cold roll forming machine processing cold-formed steel refers to forming on a cold roll forming machine so that the strip is continuously passed through the 3-20 slurry cold rolling mills arranged in series, and the forming process is performed in turn, and the finishing is rolled to the required shape.

Compared with hot-rolled steel, cold-formed steel is often a variety of varieties with smooth surfaces, thin walls, and unique shapes that cannot be produced by hot-rolling. This kind of steel has the valuable advantages of lightweight and economical use, so it is a variety that has developed rapidly in recent years.

Ⅱ. Characteristics of cold-formed steel processed by cold roll forming machine

In addition to cold-formed steel for general components, auxiliary steel for decks, and steel for guard plates, there are many types of steel. The characteristics of several of these steels are described below.

When cold-formed steel for ship structure is used as a building material, it has the following advantages:

1. The properties of steel can be reasonably utilized when designing the section shape. Compared with the previously used hot-rolled profiles, the properties are superior.

2. It has the advantages of being lightweight, high section performance, and less steel used. Material costs and basic engineering costs can be saved.

3. It has the advantages of being lightweight, easy to carry, and easy to assemble and operate on-site. From this point of view, the construction period can be shortened.

4. It has earthquake resistance, durability, and high stability in the event of a fire.