The Failure and Solution of Wall Panel Machine

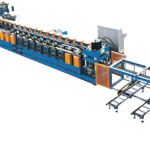

The feature of wall panel machine is that it adopts double drive twin roll extrusion process. The production process of the product is from sizing to main material, laying, compounding and re-pressing.

Wall panel machine equipment owns high-level automation, and its operation is relatively stable, its specifications can be arbitrarily adjusted. The surface of products produced by wall panel machine looks smooth and flat, and the density is also very high. It really realizes the industrial assembly line production of new building partition, reduces the cost and strength of production workers, and changes the old mode.

Any product in the use process will encounter many difficult problems or failures. Here are the basic wall panel machine failures or problems:

1. Leakage problem

If the wall panel machine is used for a long time, some parts of individual machinery and equipment may leak. There are many reasons for this problem, including the loosening or vibration of machine parts, the influence of machine heating, the problems of machine seals and pipe joints, etc. So we have to check the corresponding parts one by one to solve the problem in time.

2. Loosening problem

If the parts of wall panel machine have the deviation of geometry and fit size, they will be impacted and vibrated at the initial stage of use, and they will also be impacted by heating, deformation and other factors, resulting in very fast wear and easy loosening. So timely inspection and maintenance work is essential.

3. Motor problem

Poor lubrication of the motor may lead to the fact that the lubricating oil is not easy to form an average oil film on the friction surface of the equipment, resulting in wear. This is due to the small fit clearance of the parts of the new equipment, and it may also be due to assembly and other reasons, it is difficult to ensure the average fit clearance.

4. Human factors

It is not uncommon for operators to blindly operate the equipment according to regulations because of inadequate training or insufficient understanding of the equipment, which leads to product failure and affects product output and quality.