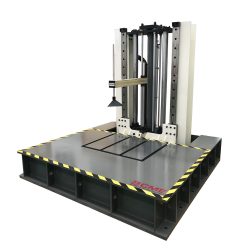

Thermal Shock Chamber

LIB thermal shock chamber has types: basket type, three-room type, and horizontal movement type. Including air to air hot cold shock test, air to liquid shock test and liquid to liquid shock test. According to different test requirements, customers choose suitable ther shock test chamber for testing.

Thermal Shock Chamber Features and Benefits

1. The thermal shock chamber has upper and lower basket type and static damper type.

2. The thermal shock test chamber can realize air-to-air, air-to-liquid and liquid-to-liquid shock test.

3. From obtaining customer needs, to discussing solutions, production, transportation, installation and commissioning, LIB can realize one-stop solutions.

4. The thermal shock chamber is mainly used in high and low temperature shock test of automobiles, EV batteries, electronic products and etc.

Specifications of Thermal Shock Chamber

Model

TS-162

TS-340

TS-500

TS-1000

Internal Dimensions (mm)

300*300*250

450*450*360

650*650*500

850*850*700

Overall Dimension (mm)

1560*870*1545

1710*1020*1845

1910*1220*2265

2110*1420*2665

Interior Volume (mm)

22L

72L

211L

505L

Loading Capacity

20kg

30kg

50kg

60kg

Pre-heat Room

Upper limit Temperature

+220℃

Heating Time

Ambient ~ + 200℃, within 30 minutes

Pre-cool Room

Lower limit Temperature

-75℃

Cooling time

Ambient ~ -70℃, within 30 minutes

Test Room

High Temperature Exposure Range

Ambient +20 ~ +200°C

Low temperature Exposure Range

–65 ~ -5°C

Temperature Fluctuation

≤±0.5℃

Temperature Deviation

≤±3 ℃

Temperature Recovery Time

Within 5 minutes

Cooling System

Mechanical compression refrigeration system

Controller

Programmable color LCD touch screen controller, Ethernet connection

Safety Device

Over-temperature protection, Over-current protection; Refrigerant high-pressure protection; Earth leakage protection

Exterior Material

Steel Plate with protective coating

Interior Material

SUS304 stainless steel

Observation Window

Interior lighting, double-layer thermo stability silicone rubber sealing

Standard Configuration

2 shelves.