Understanding the Significance of Bursting Strength Test

The bursting strength test is a crucial assessment used to determine the strength and durability of various materials, particularly in industries such as packaging, textiles, and paper manufacturing. This test helps in evaluating the ability of a material to withstand pressure and resist bursting or tearing under controlled conditions. In this article, we will delve into the importance of the bursting strength test and its practical applications.

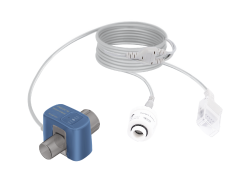

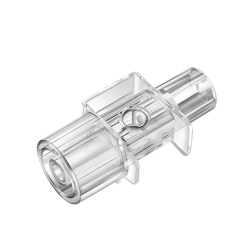

Understanding the Test: The bursting strength test involves subjecting a material to increasing pressure until it ruptures. The test is conducted using a specialized instrument known as a bursting strength tester. It consists of applying hydraulic pressure to a circular or diaphragm-shaped area on the material until the point of rupture. The test determines the maximum pressure the material can withstand, expressed in units such as pounds per square inch (psi) or kilopascals (kPa).

The Test Procedure: To conduct the bursting strength test, a specimen of the material is securely clamped over the diaphragm of the testing apparatus. The diaphragm is then exerted with increasing pressure until the material ruptures. The maximum pressure recorded at the point of failure represents the material’s bursting strength.

Applications:

Packaging Industry: The bursting strength test plays a vital role in ensuring the reliability and safety of packaging materials. Packaging materials, such as corrugated boxes, paperboard cartons, or plastic films, need to withstand the rigors of transportation and handling without bursting or tearing. This test helps manufacturers select materials with appropriate bursting strength to ensure the integrity of the packaging.

Textile Industry: Fabrics used for various applications, such as apparel, upholstery, or industrial use, must possess sufficient bursting strength. This ensures that the fabric can endure everyday stresses without tearing. The test helps textile manufacturers gauge the durability and quality of their products.

Paper Industry: The bursting strength of paperboard and paper used in products like cardboard boxes or envelopes is critical to ensure their ability to withstand compression and rough handling during storage and transportation. By conducting the bursting strength test, paper manufacturers can ensure their products meet the required standards.

Quality Control: The bursting strength test is an essential part of quality control in industries that deal with materials under pressure. It allows manufacturers to assess the strength and performance of their materials, enabling them to identify weak points and make necessary improvements.

Conclusion: The bursting strength test is a significant evaluation method used across various industries to determine the ability of materials to withstand pressure and resist bursting or tearing. By conducting this test, manufacturers can ensure their products meet quality standards and fulfill their intended purposes. It enables them to make informed decisions about material selection, enhancing product reliability, and overall customer satisfaction.