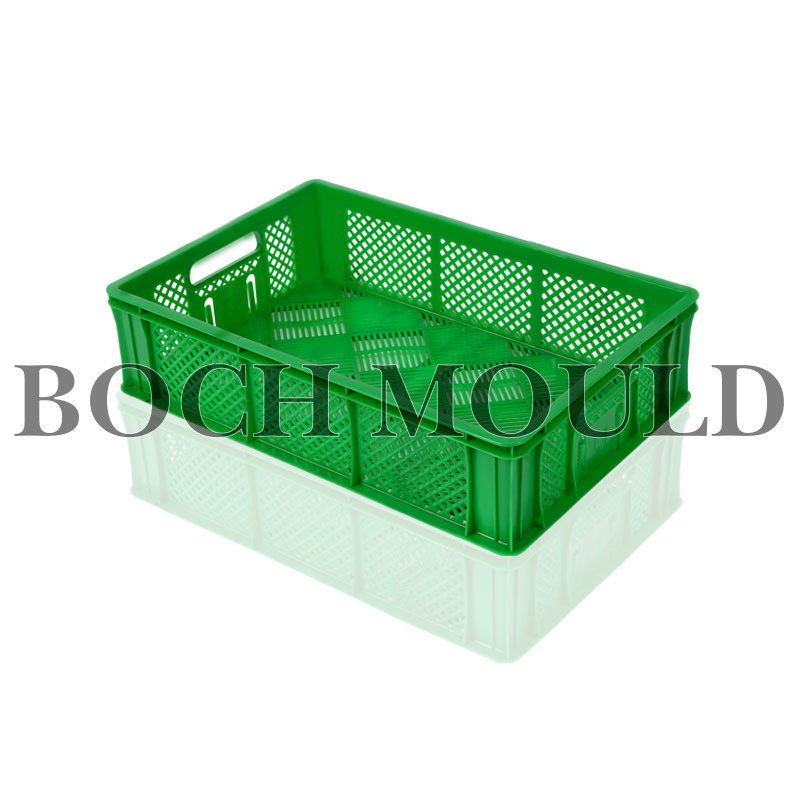

What Are Some Of The Limitations Of Using Fruit Basket Moulds?

There are several limitations associated with using Fruit Basket Moulds in the manufacturing of plastic fruit baskets. These limitations include:

(1)Production volume: While Fruit Basket Moulds are well-suited for high-volume production, they may not be cost-effective for small-scale manufacturing operations.

(2)Design constraints: The design of a Fruit Basket Mould can significantly impact the final product. Design limitations such as wall thickness, part geometry, and undercuts can restrict the Mould’s design capabilities and limit the types of fruit baskets that can be produced.

(3)Tooling costs: The upfront costs associated with creating a Fruit Basket Mould can be expensive. The cost of the Mould can depend on factors such as the size, complexity, and number of cavities in the Mould.

(4)Material selection: The type of plastic used in the injection Moulding process can impact the final product’s quality and durability. The selection of plastic material must consider the intended use of the fruit basket and the environment in which it will be used.

(5)Maintenance and repair: Fruit Basket Moulds require regular maintenance and repair to ensure optimal performance. Failure to maintain and repair the Mould can lead to decreased production quality, increased downtime, and additional repair costs.