What is a Printed Circuit Board ?

In today’s digital age, electronic devices have become an indispensable part of our daily lives. Whether it’s a smartphone, computer, or medical equipment, their core component is the Printed Circuit Board (PCB). A PCB is a crucial element in electronic devices, organizing electronic components in an orderly manner by providing mechanical support and electrical connections to form complex circuits. This article delves into the definition of PCBs, their evolutionary history, manufacturing processes, different types, and their widespread applications across various industries.

Definition and Evolutionary History of PCBs

The history of Printed Circuit Boards dates back to the early 20th century, with commercial applications emerging in the 1950s. Engineer Paul Eisler is credited as the pioneer of PCBs, introducing the concept of printing conductive patterns on circuit boards. This innovation revolutionized modern PCB manufacturing, replacing traditional manual wiring methods and becoming an indispensable core component in contemporary electronic devices.

Manufacturing Process of PCBs

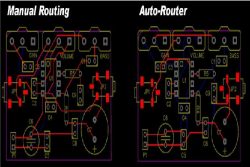

Design Phase: PCB manufacturing begins with the design of the circuit diagram using Computer-Aided Design (CAD) software. Designers use this software to draw the circuit diagram, determining the layout and connections of electronic components.

Prototyping: After design completion, manufacturers create a prototype of the PCB. This phase involves converting design files into physical samples to validate the accuracy and feasibility of the design.

Production Phase: Once the prototype is confirmed, PCBs enter mass production. Manufacturers select suitable substrate materials and utilize processes such as printing, etching, and drilling to progressively produce the PCB.

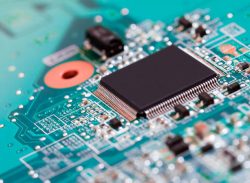

Assembly: Electronic components are precisely installed onto the finished PCB and connected to the conductive patterns through methods like soldering.

Types of PCBs

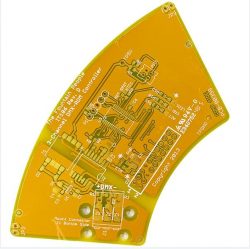

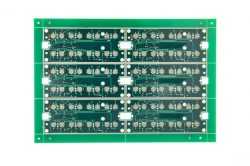

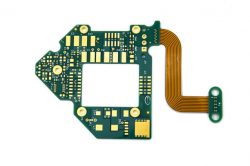

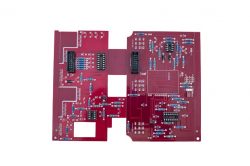

Based on application scenarios and structural characteristics, PCBs can be categorized as single-layer, double-layer, and multi-layer. Single-layer PCBs are suitable for simple circuits, while double-layer and multi-layer PCBs accommodate more components and intricate circuit designs. Additionally, PCBs can be rigid, flexible, or a combination of both (rigid-flex PCBs), depending on the material used.

Rigid PCBs: Commonly used and suitable for various applications due to high mechanical strength and stability. Found in computers, communication devices, etc.

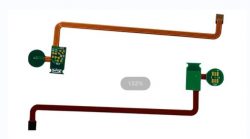

Flexible PCBs: Utilize flexible base materials, allowing bending and folding. Applied in medical instruments, portable electronics, etc.

Rigid-Flex PCBs: Combine the strengths of rigid and flexible PCBs, ideal for applications in automotive electronics, aerospace, and more.

Widespread Applications of PCBs

PCBs find extensive use in various electronic devices, including computers, communication equipment, consumer electronics, medical instruments, and more. In modern society, nearly all electronic products rely on PCBs. Their pivotal role in the electronics industry has driven rapid technological advancements, opening up possibilities across diverse sectors.

Future Trends in PCB Development

As electronic technology continues to innovate, PCBs are poised for new developments. Trends such as flexible PCBs, high-density interconnect technologies, and advanced material applications will be key directions in future PCB manufacturing. The demand for intelligence and miniaturization will further propel the extensive application of PCBs, contributing to technological progress in various fields.

By gaining a comprehensive understanding of the definition, history, manufacturing processes, types, and applications of PCBs, we can better grasp the critical role these electronic components play in modern technology and their crucial contribution to advancing science and technology.

If you want to have a deeper understanding of printed circuit boards, check out TechSparks’ blog post What Does PCB Stand for in Electronics.