Zirconia Fused Alumina

Zircona fused alumina is made of alumina and zirconia as raw materials and is smelted at a high temperature above 2200 ℃ in an electric arc furnace. It is a kind of fused alumina containing 10% to 40% of zirconium dioxide (ZrO2).

Types of Zirconia Fused Alumina

Zirconia Fused Alumina 25

Zirconia Fused Alumina 40

Zirconia Fused Alumina Features

Refractory/Fireproof

Zirconia Fused Alumina contains Zirconium Oxide(ZrO2) and Aluminium Oxide(Al2O3) which are important chemical contents for refractory performance. Ideal material for refractory bricks.

High Strength

Zirconia Fused Alumina has high hardness and strength(about 400N). It’s one of the most hard and strong artificial corundum.

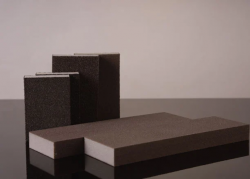

Sharp Grain

Like other corundum, grains of ZA is sharp edged material ideal for cutting, lapping, polishing etc of metal surface.

High Density

Zirconia Fused Alumina has true gravity of about 4.3g/cm3, compared to about 3.9g/cm3 of Brown Fused Alumina and 3.6g/cm3 of White Fused Alumina. And bulk density about 2.2g/cm3 which is also much higher than other fused alumina. It’s used for heavy duty bonded abrasive products.

Faqs of Zirconia Fused Alumina

What is zirconia alumina abrasive?

F grade are specifically used for bonded abrasives. From rough, organic-bonded abrasives to precise, vitrified-bonded abrasives, we offer a wide range of products that can be customized for various applications. F grade can be used to increase removal rate of material and to extend usability without influence for the beautiful finishes.

P grade are specifically used for coated abrasives. While the traditional grains are dull or broken at the bonding point, P grade grains is characterized with unique fracture to offer microscopic precision in performance and efficient ability during high speed cutting. These grains not only improve the overall cutting, but also extend the usability of the sandpapers, belts, or flap discs.

What are the advantages of zirconia fused alumina?

1). Zircona fused alumina sand has the characteristics of compact structure, high hardness, good wear resistance and large specific gravity, and can be used as abrasive to grind and polish steel castings, alloy steel, carbon steel, hard bronze and other workpieces.

2). Zircona fused alumina has high mechanical strength, good thermal shock resistance, high temperature resistance and corrosion resistance, and is a high-quality refractory material.

3). Good slag corrosion resistance and low thermal expansion coefficient, commonly used in glass kiln lining refractory bricks or refractory castables.

Are you producing desiliconized zirconium?

Actually desiliconized zirconium is one of our advantageous products, and it can be customeized to meet the different applications.